TECHNOLOGY

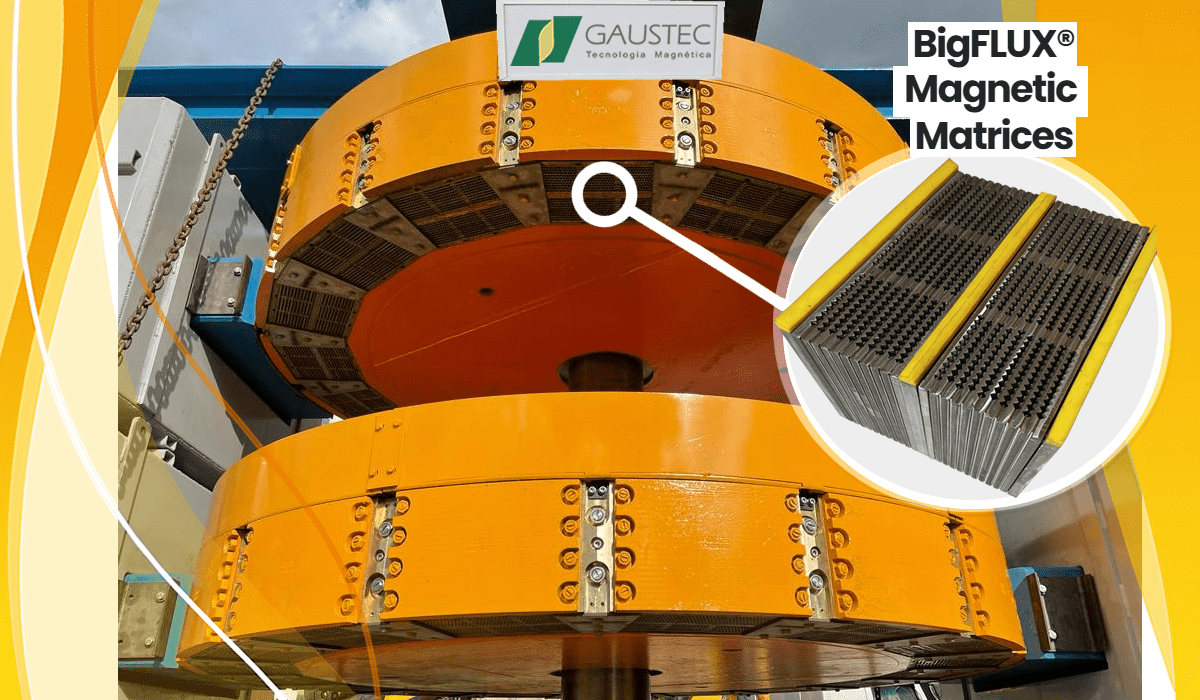

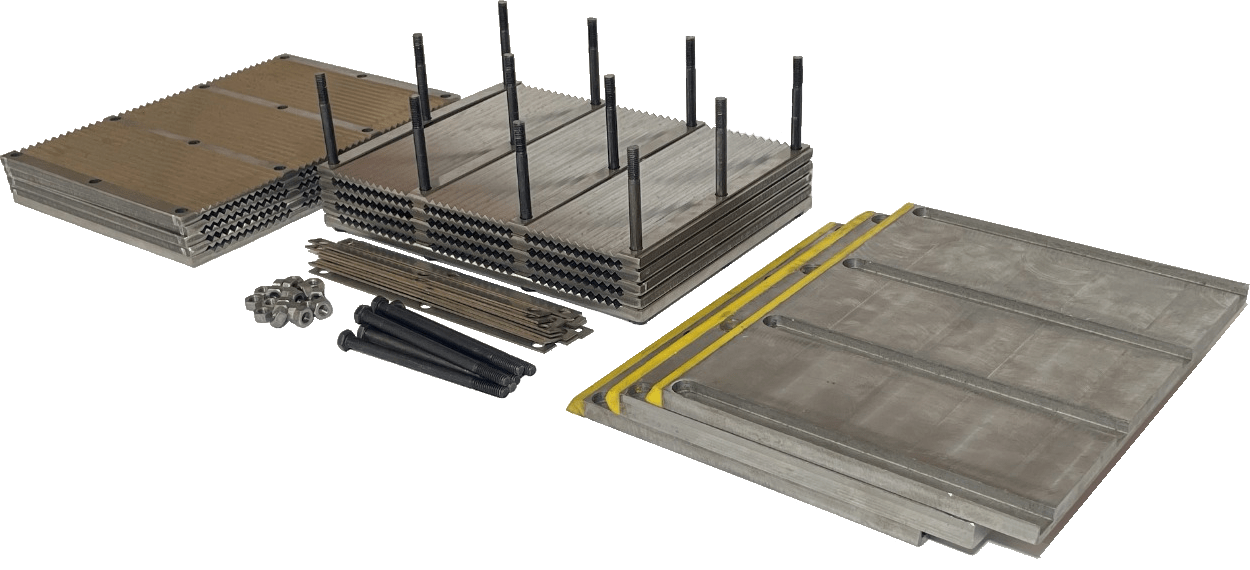

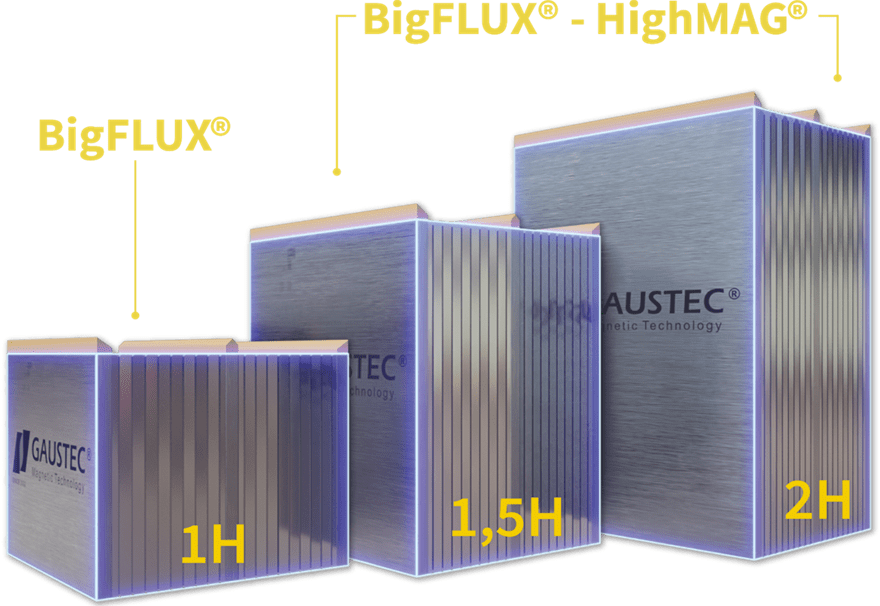

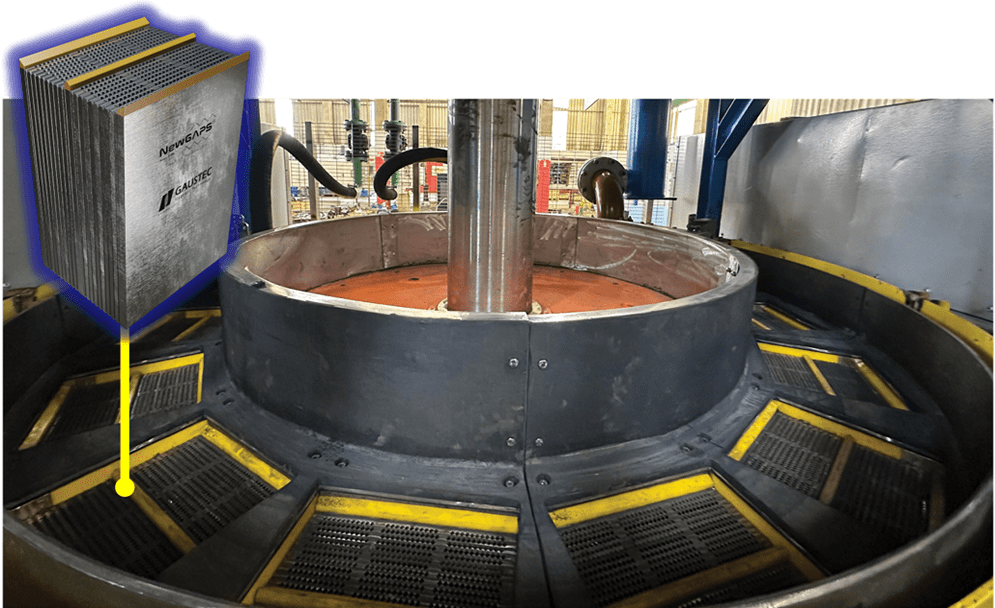

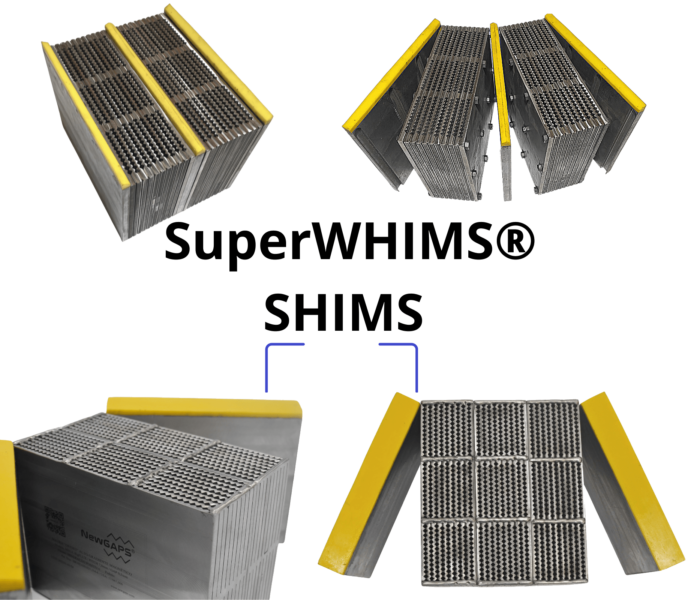

Magnetic Separation Process - BigFLUX® Magnetic Matrices

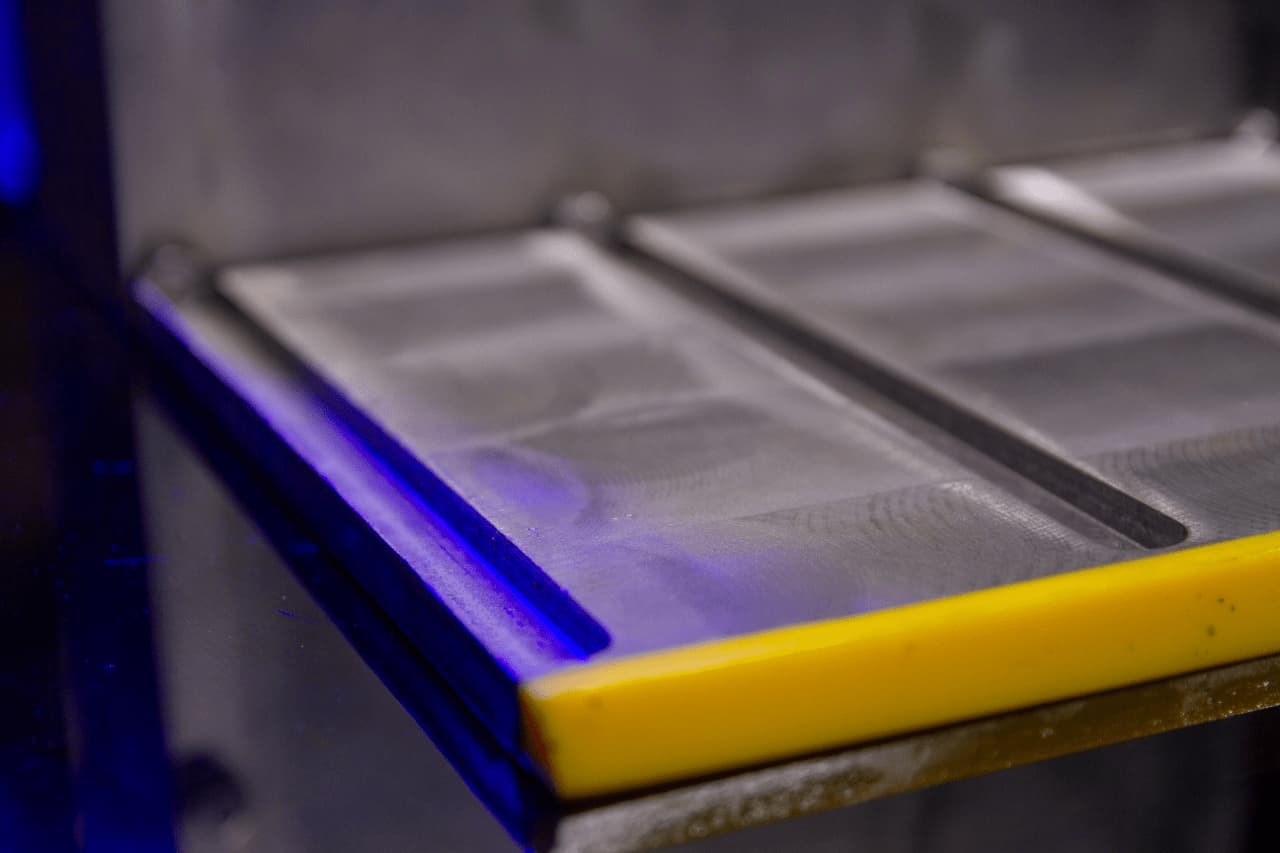

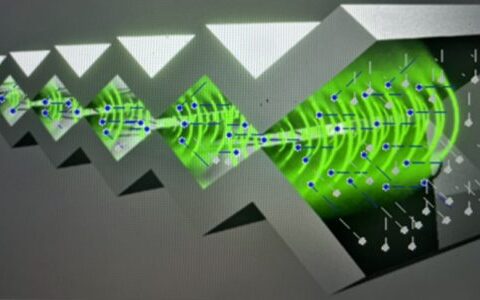

Behavior of BigFLUX® magnetic matrices during the process of magnetic separation of ore and silica

The new decisive variables for the recovery of fine and ultrafine mineral particles

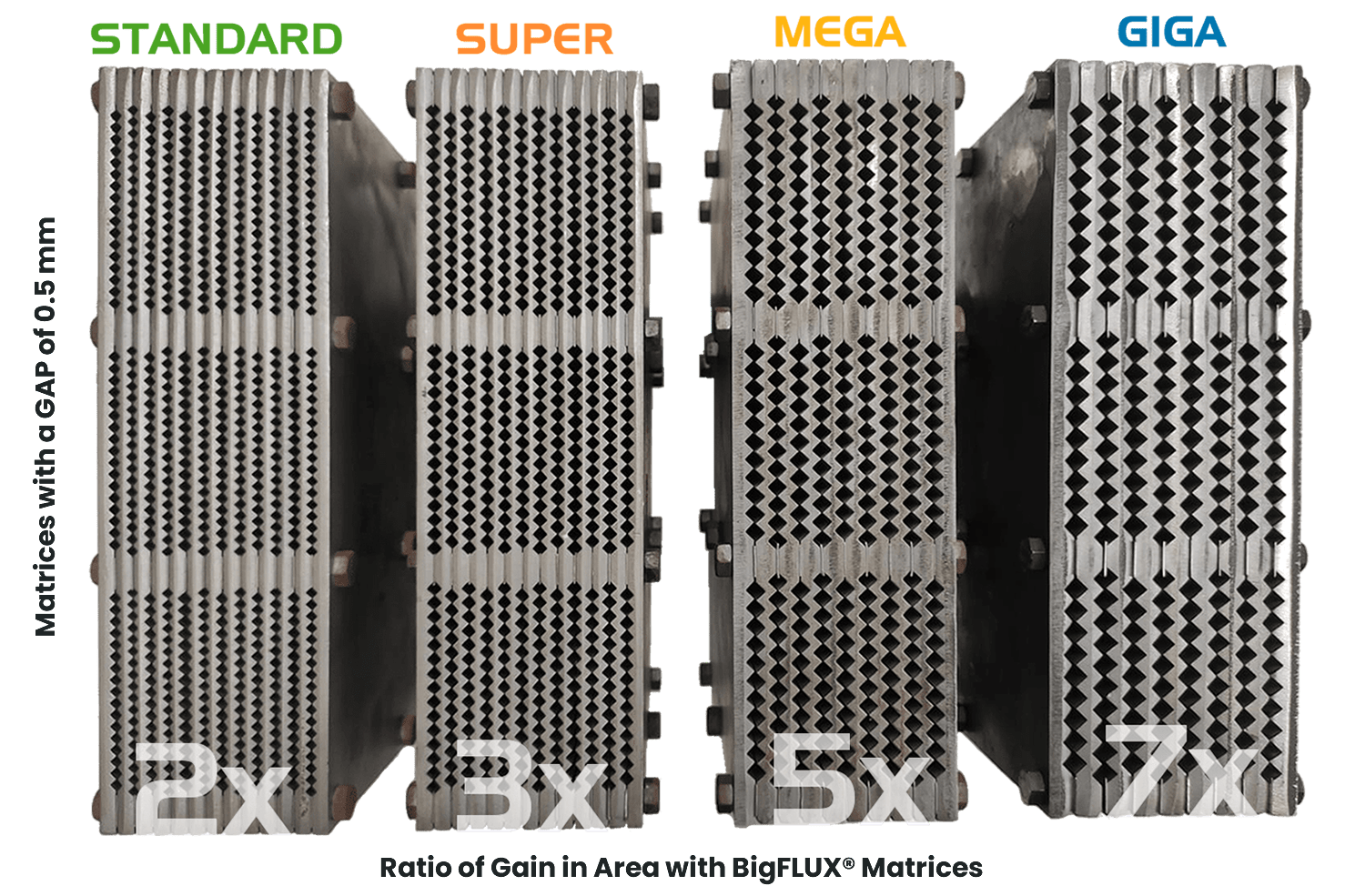

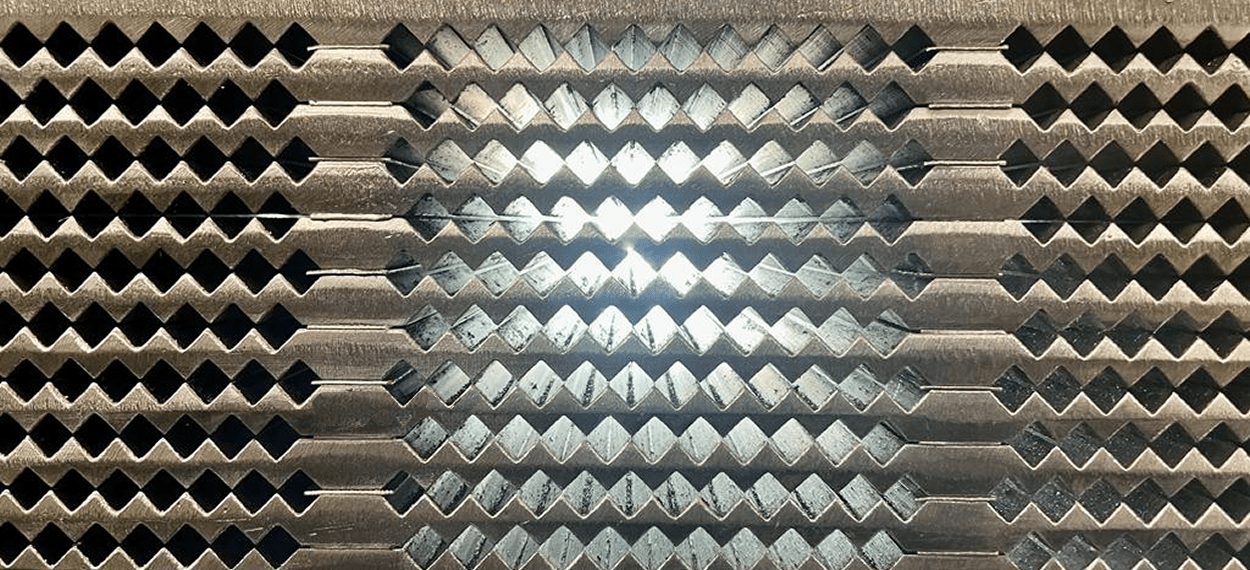

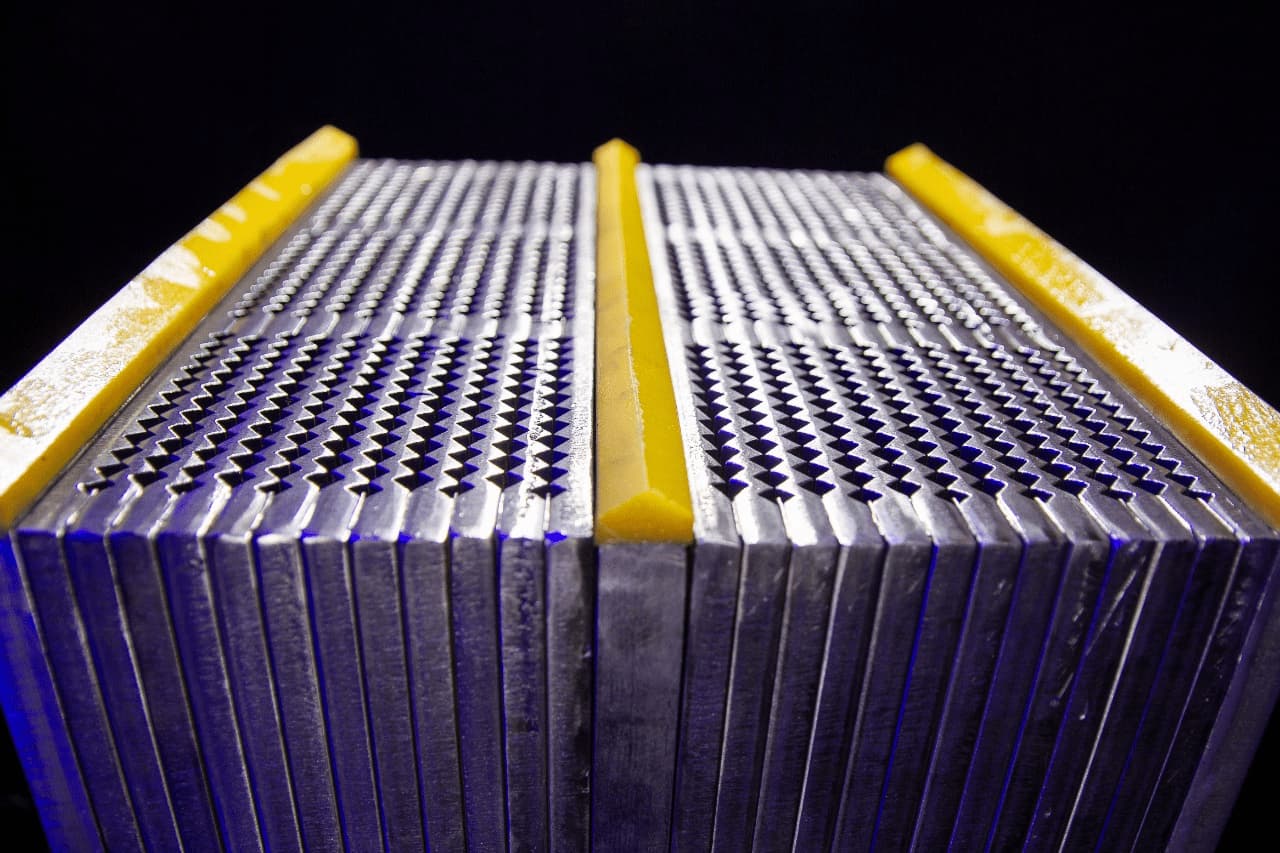

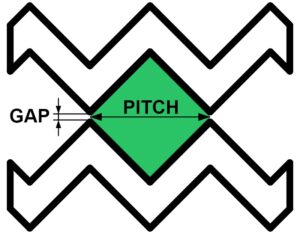

Pitch

Pitch (size of teeth) is the new process variable that allows for greater slurry flow, higher magnetic fields and magnetic gradients. This new variable also allows the unprecedented use of closed gaps of up to 0.5 mm without causing clogging, ideal for particles below 37 microns.

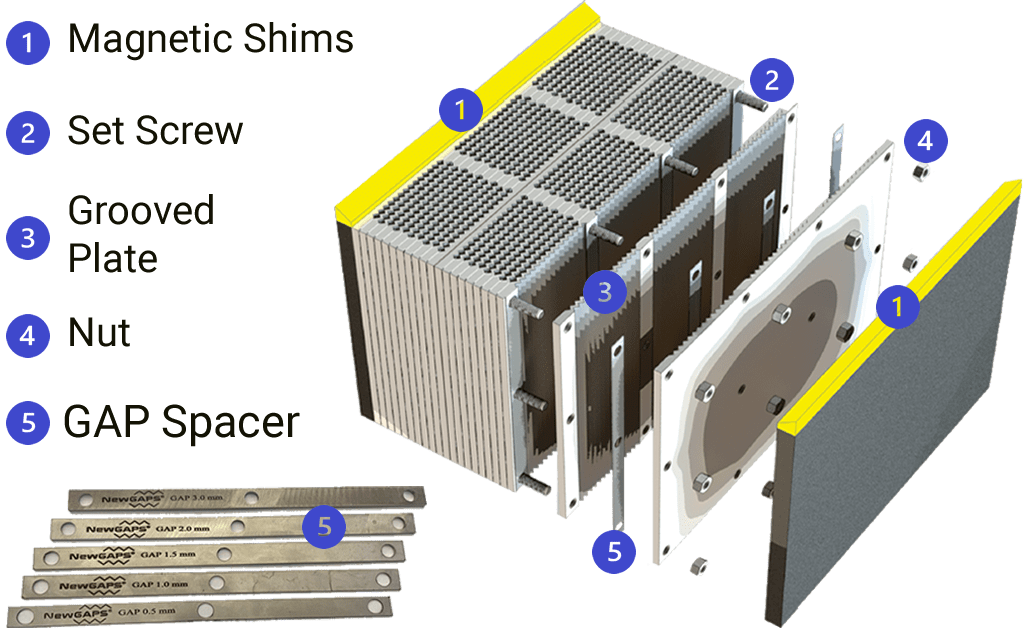

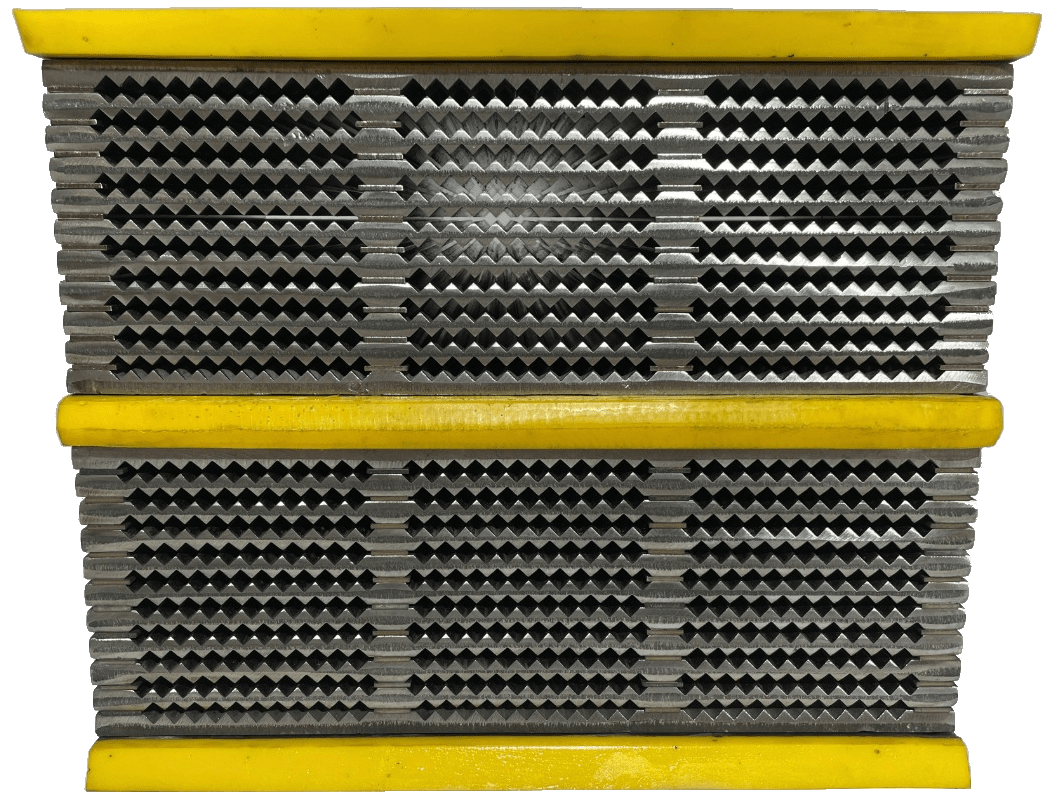

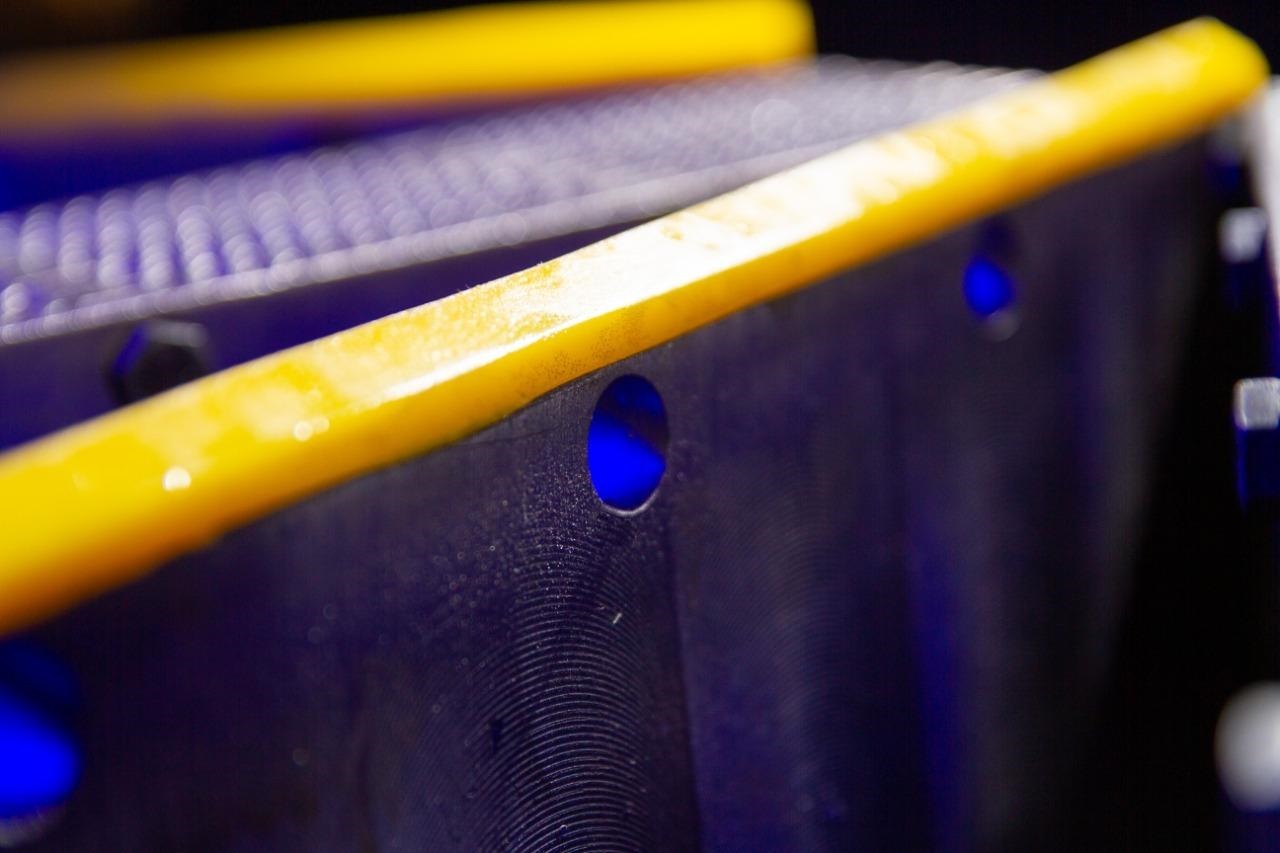

Offset Design

The new construction form OFFSET was developed to adjust the different sizes of teeth (Pitch) and avoid the mechanical weakening of the grooved plates. The result was an increase of more than 15% in the magnetic efficiency of the BigFLUX® magnetic matrices without having to change the Jones/WHIMS coils.

More Efficient Magnetic Separation Process

High Economic Gain