Watch NewGAPS’ Institutional Video

Learn more about our technologies that are revolutionizing magnetic separation in mining companies, providing better quality for the concentrated product, and making a co-product available for sale.

BigFLUX® High Efficiency Magnetic Matrices

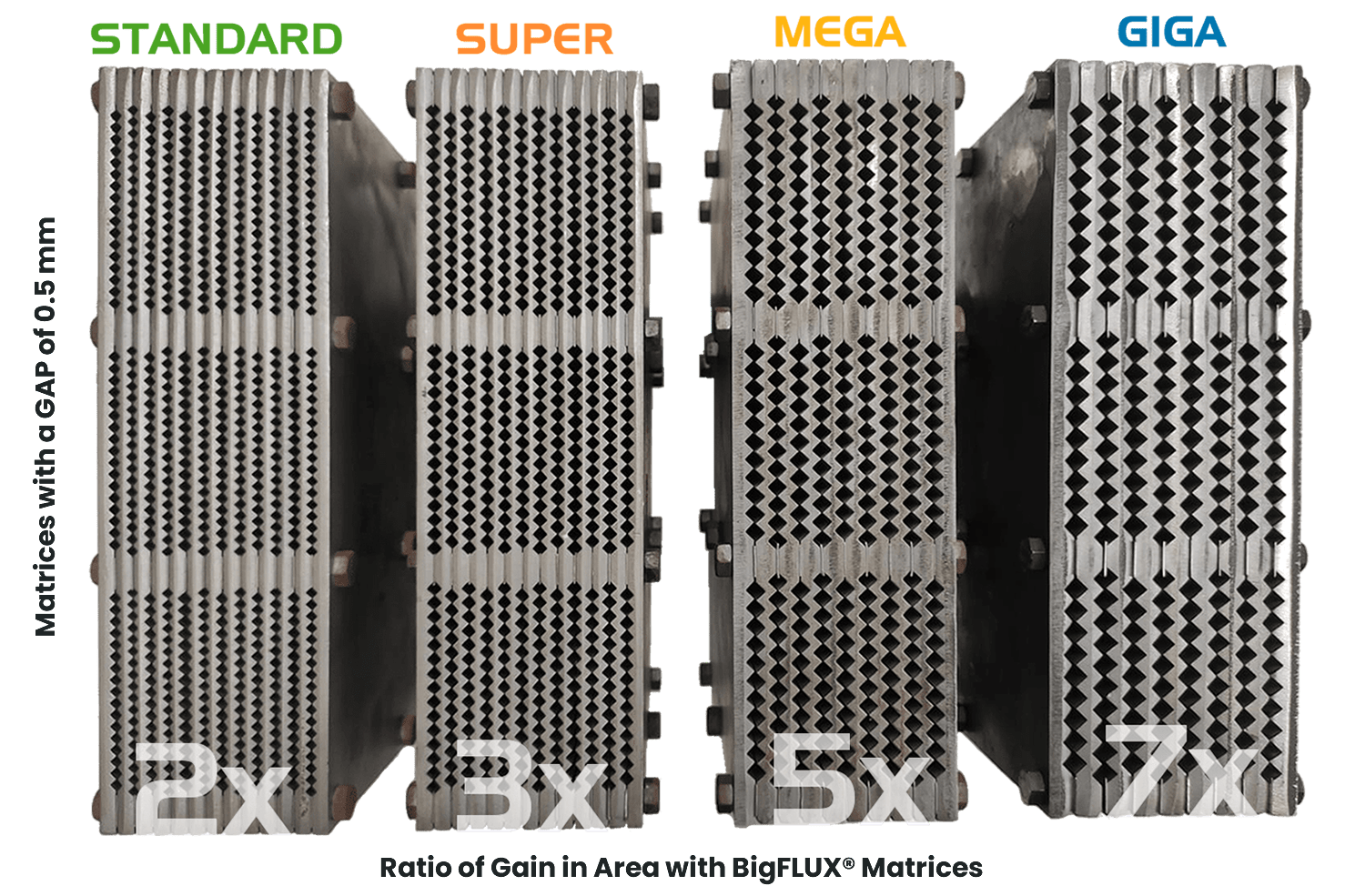

NewGAPS is a company specialized in technological solutions for the recovery of fine and ultrafine iron ore particles for Jones/WHIMS type magnetic separators. Through studies and tests in laboratories, NewGAPS developed the new BigFLUX® magnetic matrices, which are revolutionizing magnetic separation. Its new grooved plates with large teeth – PITCH and the new design – OFFSET amplify the magnetic field and magnetic gradients allowing greater efficiency for the process of concentration of magnetic minerals.

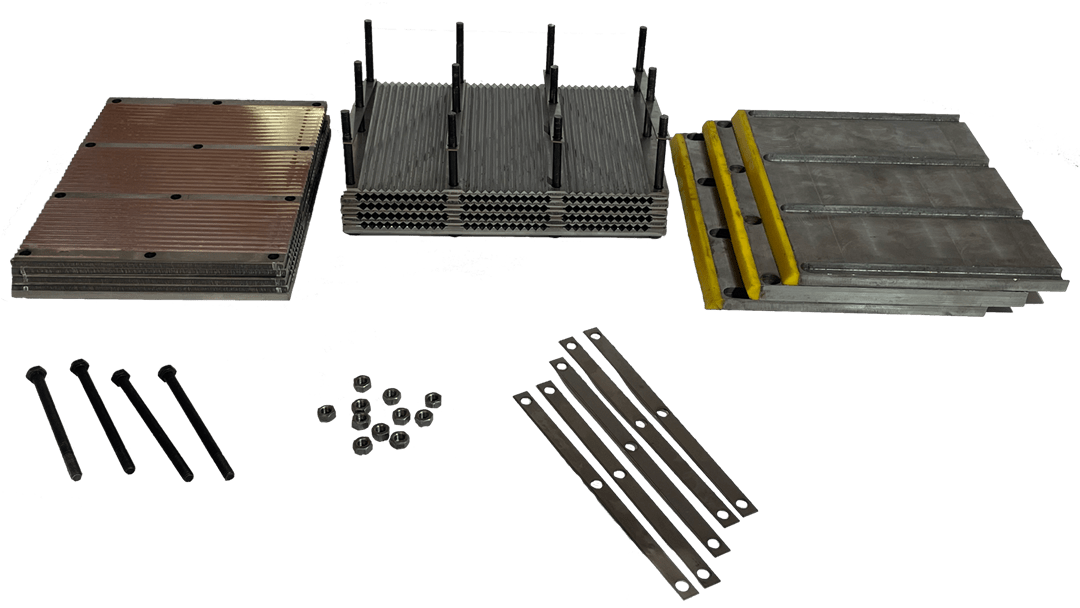

BigFLUX® Magnetic Matrices with FlexGAP® Technology

In addition to the BigFLUX® technology, NewGAPS presents another great innovation, the BigFLUX® magnetic matrices with FlexGAP® technology - adjustable GAP, which allows you to easily adjust the distance between the ends of the grooved plates - called GAP. These new technologies are providing great benefits for magnetic separation, as they are recovering not only the fine iron ore particles, but also the ultrafine ones below 10 microns, hitherto wasted in the tailings.

MAGNETIC MATRIX

BigFLUX®

- Higher feed capacity

- Higher magnetic field

- Higher magnetic attraction force

- Higher magnetic gradient

- Low risk of clogging

- Improved efficiency of concentrate discharge and medium washing sprays

BigFLUX® MAGNETIC MATRIX

FlexGAP® Technology

- Easily adjustable GAPS

- Flexibility to adjust magnetic separation processes

- Reduction of operating costs

- Numerous options for adjusting the GAPS distance (0.5 mm to 5 mm)

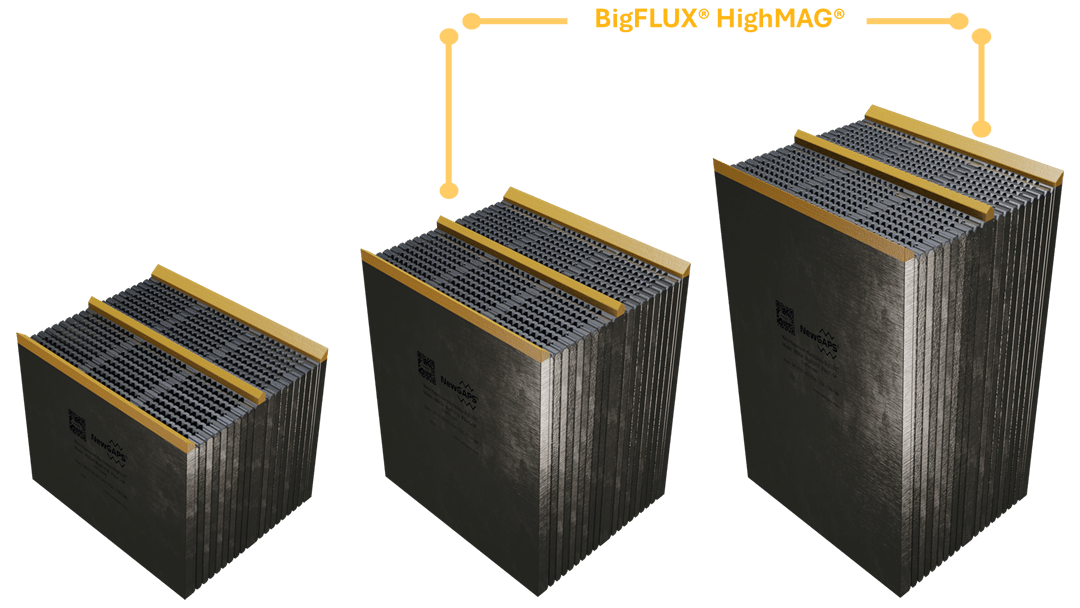

BigFLUX® MAGNETIC MATRIX

HighMAG® Technology

- Greater recovery of ultrafines below 0.045 mm (45 microns) present in tailing dams.

- Lower hydrodynamic drag.

- Reduced investment cost in Magnetic Separators

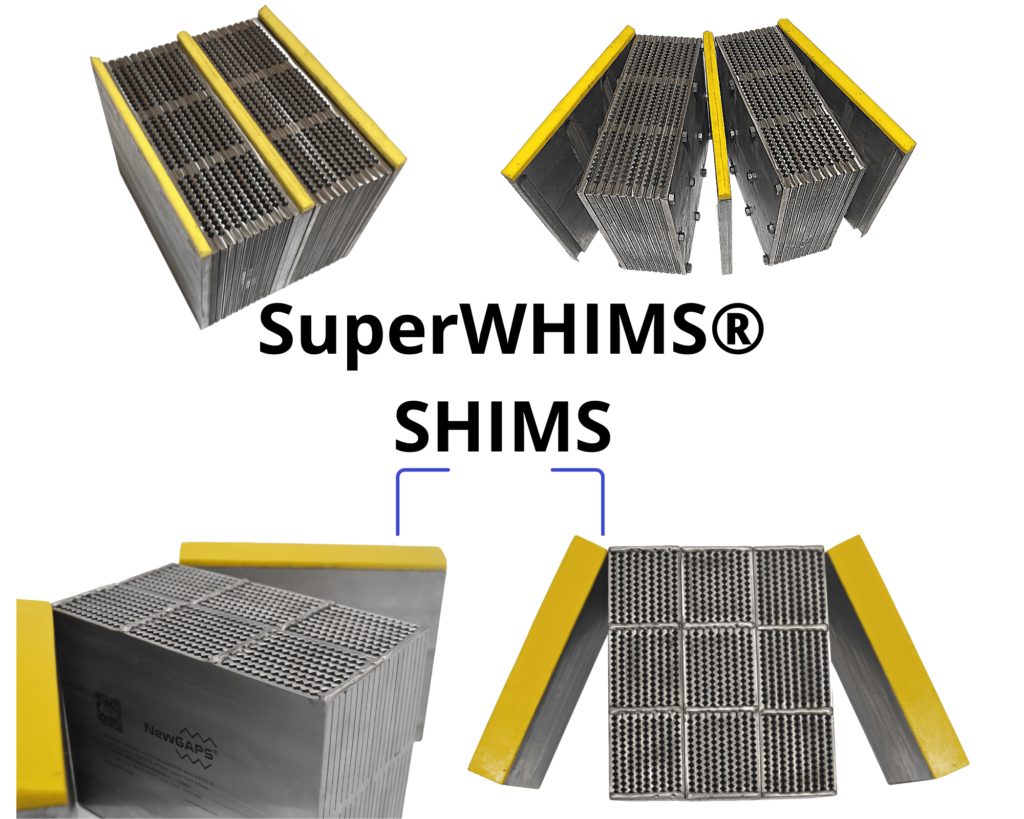

MAGNETIC SHIMS

SuperWHIMS®

- They provide better quality of the magnetic concentrate

- They enable greater production of magnetic concentrate

- They are used to boost magnetic field strength

- They protect the fastening elements of BigFLUX® / FlexGAP® matrices

- They allow the production of product and co-product from tailings reprocessing

Our Diferentials

NewGAPS’s team has professionals with extensive experience in magnetic separation. All knowledge is used to develop the best solutions, and thus obtain maximum efficiency in the high intensity magnetic separation process.

We have a specialized team to analyze the characteristics of the ore supplied by the customer, and to understand the needs of each process. After analysis, we define the best configuration of BigFLUX® magnetic matrices to maximize the production of each customer.

In partnership with GAUSTEC Magnetism Mineral Processing Research and Development Center, we provide all support and guidance for the development of the best process route, allowing the excellent use of minerals.

NewGAPS offers specialized training in the unprecedented BigFLUX® and FlexGAP® technologies, as well as other topics within Magnetic Separation: Process, Operation and Maintenance, so that our customers and partners obtain the best results from our technologies.

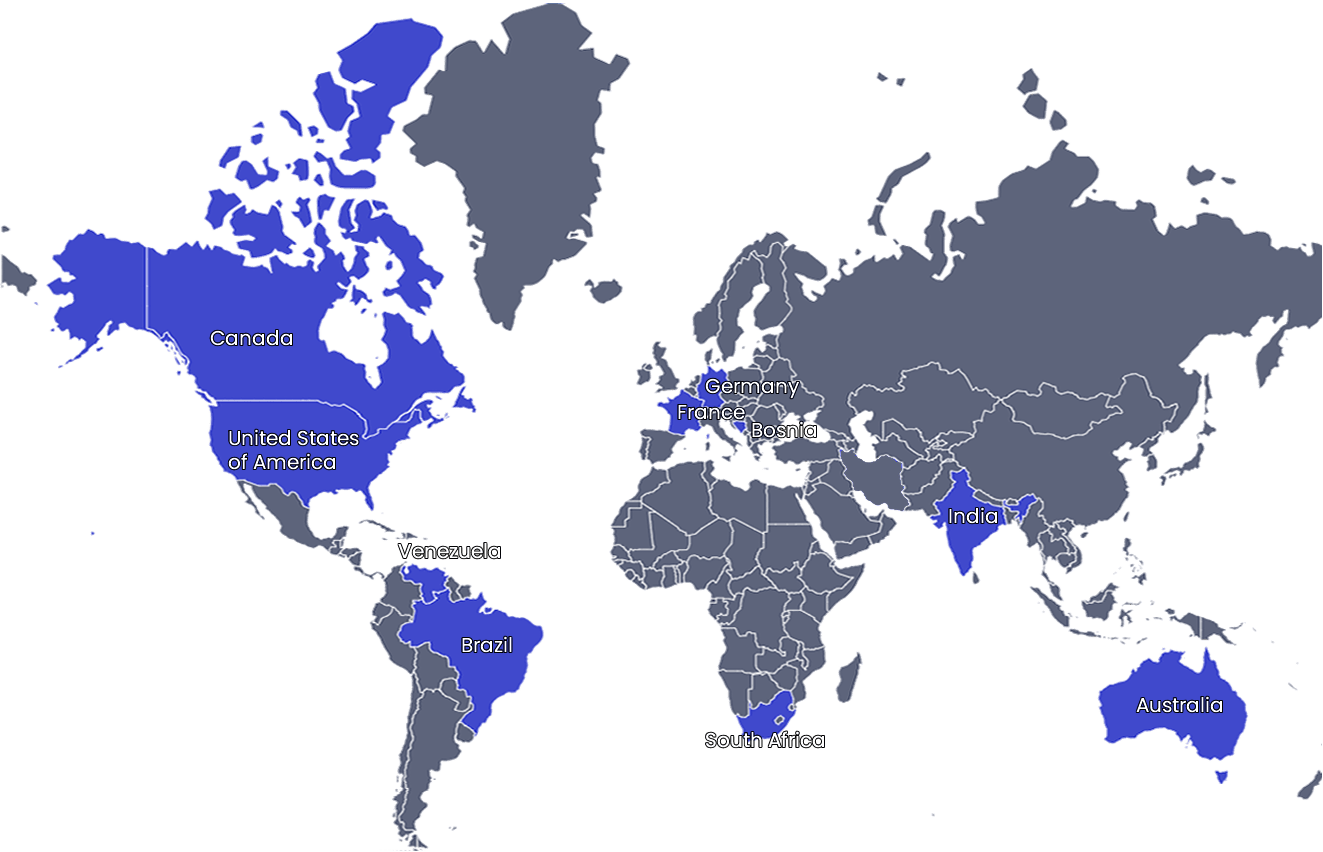

Our Customers

We are trusted by some of the largest companies in the world.